|

|

110V 2200LB

Digital Display Welding Roller Rack |

|

|

|

|

|

|

|

|

Product

Overview |

|

The Connected Welding Roller Rack

is a professional mechanical device for assisting in welding cylindrical

or annular workpieces, and can be matched with welding operation

machines, submerged arc welding machines, etc. The machine is mainly

applied to welding of pipelines include the inside and outside of pipes,

can drive the workpieces to rotate at the uniform speed and can improve

the welding efficiency and quality. |

|

Product

Parameters |

|

Model |

XH-1T |

|

Working Voltage |

AC 110V 60Hz |

|

Power |

120W |

|

Load Capacity |

1000KG (2200LB) |

|

Speed Range |

100~1000mm/min |

|

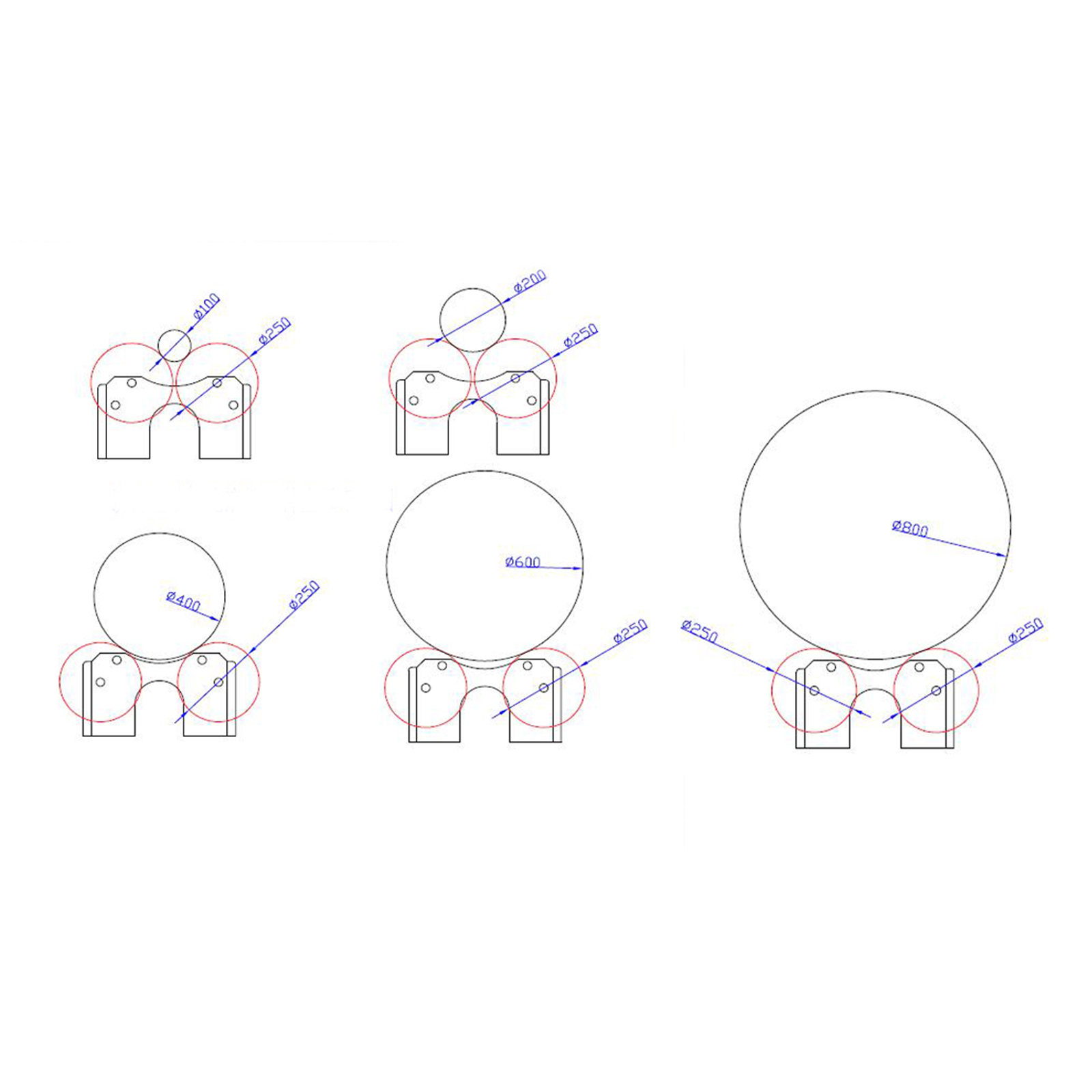

Diameter Range |

20~800mm |

|

Roller Type |

50mm (W) × 250mm (D) |

|

Operation Method |

Control Box Operation |

|

|

|

Product

Features |

|

|

A. Automatic Switch

B. Power Switch

C. Foot Switch

D. Forward/Reverse Switch

E. Speed Adjustor

F. Speed Displayer

|

|

|

|

|

Digital Display Control Box

Multiple switches are integrated on the control box and

facilitate integrated control over the operation. The speed is

digitally displayed and set on the control box, the user can

observe the running speed more directly and visibly, the

operation difficulty of workers is reduced, and the processing

effect can be well guaranteed.

|

|

High-Quality Motor

The motor drives rollers to rotate through the transmission

mechanism so that the workpiece can stably rotate on the

rollers, and continuous adjustment of the welding position can

be achieved. The rotating speed can also be controlled to meet

the welding requirements of the workpieces with different

diameters and materials. Operation is stable, and the noise is

low.

|

|

Polyurethane Wheels

The roller wheels are made of polyurethane materials, the

friction between the roller wheels and the workpiece can be

increased, the roller wheels are resistant to temperature and

wear and free of slippage, stable rotation of the workpieces can

be effectively ensured, and the welding effect is better

achieved.

|

|

|

|

|

Driving Frame

The driving frame well supports the driving rollers in the

working process so that the driving rollers can stably run and

support the workpieces. The control box is also installed on the

side of the driving frame and controls the rollers to rotate

slowly and smoothly.

|

|

Speed Reducer

As a key transmission part, the speed reducer can run stably and

is good in transmission performance. The motor speed can be

reduced, and the output torque can be increased, thereby

ensuring the rollers can drive the heavy workpieces at a stable

and controllable speed. The speed reducer can be matched with

the motor to achieve well operation of the roller rack.

|

|

Foot Switch

The foot button and the automatic button are arranged on the

control box, the foot switch can be controlled by the foot

button, the operator can freely select the control mode to meet

different demands, rotation of the workpieces can be flexibly

controlled in the operating process, and the convenience and

safety of welding operation are improved.

|

|

|

|

|

Adjustable Mounting Holes

The corresponding roller shaft mounting holes can be selected

according to the diameters of the workpieces, and the lower

mounting holes can be used when the diameter of a pipeline is

larger than or equal to 400mm. The included angle between the

rollers and the workpiece can be adjusted, the roller rack can

better adapt to different workpieces, operation is convenient,

easy and quick, and time and labor are saved.

|

|

Linkage Control Mode

The welding roller rack can be combined with other devices, such

as welding equipment, positioners and conveying systems in the

actual production process, thereby achieving efficient and

automatic welding. The welding accuracy can be improved, manual

intervention can be reduced, and the production efficiency can

be improved.

|

|

|

|

|

Placement of

Workpieces with Different Diameters |

|

|

Attention |

|

Before operating the unit, please read

this instruction book thoroughly, and retain it for future reference. |

|

1. The machine should be placed at a dry, clean,

ventilated and horizontal position, and the operation of the machine

should be horizontal and smooth. Keep away from flammables and

explosives. |

|

2. For safety reasons, the device must be connected

to a reliable safety grounding device and must have three feet with

ground connection. |

|

3. Unplug the

power cable/cord if the machine will not be used in a long time. |

|

Application |

|

The Connected Welding Roller Rack

can assist the workers in pipeline welding, and can be well applied to

the fields of engineering machinery, pressure vessel manufacturing,

ocean engineering, automatic production, etc. It is suitable for plasma

cutting, flame cutting, flange welding, surface polishing, surface

spraying and other production processes and is an ideal device for

industrial production. |

|

|

Maintenance

Information |

|

Users are responsible for the

proper operation and maintenance of the equipment they use. Some

equipment will quickly become damaged and unsafe if abused or subjected

to improper demands. If the equipment is regularly maintained and not

abused, you will get the maximum safety and service performance from

your equipment. |

-

Do not overload equipment.

|

-

Do not use overcharged voltage.

|

-

Do not use hands to stop the roller when the machine

is working.

|

|

Product

Display |

|

|

|

|

|

Item Number (022454): |

|

| Name |

PCS |

| Connected

Welding Roller Rack |

1 |

| Foot

Switch |

1 |

|

Control Box |

1 |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |